La Coutellerie Nontronnaise

The Nontron knife bears the name of the village of its birth. Its story is so long and filled with legends that it is difficult to date. However, experts agree on the fact that the Nontron knife is the oldest French knife.

The Nontron knife, the oldest knife of France

Guillaume de la Villeneuve was already referring to «Pierregord knives» in hi...

The Nontron knife bears the name of the village of its birth. Its story is so long and filled with legends that it is difficult to date. However, experts agree on the fact that the Nontron knife is the oldest French knife.

The Nontron knife, the oldest knife of France

Guillaume de la Villeneuve was already referring to «Pierregord knives» in his «Nomenclature des crieries de Paris »at the beginning of the 13th Century. It is possible that this region of Southern France produced knives and other sharpened tolls before the Middle Ages.

All the raw materials were indeed gathered in site. The mineral iron (nontronite), long operated by Gallic people called Petrocorii (forges of Azat-in-Nontronnais, among others) and the numerous box trees. The blades were hardened near the village in the very cold pure waters of the Bandiat River. Strabon of Amasea, Greek geographer and historian who was a contemporary of Julius Caesar and a world traveler, described the Petrocorii as excellent iron workers.

In the 14th Century, the glossary of St-Palaye reported the writings of the poets that were paying tribute to these cutting Tools. At that time, the Parisian "Compagnons du devoir" (fine journeyman) used to visit Nontron during their trip around France. This is certainly this reputation for excellence in metal working that explains why the King of France Charles VII, also called "the Victorious" (crowned by Joan of Arc) would have ordered his sword to Nontron ironsmiths.

On October 13th 1653, Guillaume Legrand, master cutler in Saint Eustache (Paris) married Marie Belleterie and settled in Nontron, the village of his wife to manufacture Nontron knives. It is at that period that we can find the first writings concerning the turning ferrule.

According to the Inspector from the Manufactures and Industries of Bordeaux, there were 35 cutleries in the Perigord area in 1788. At that time, with 2800 inhabitants, the Nontron village counted only 8 knife makers working in 5 renowned cutleries.

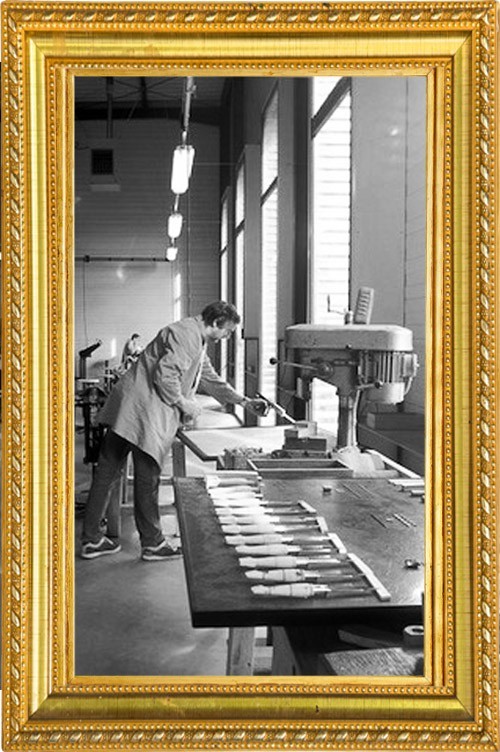

The great steps in the making of the Nontron knife

Forging

All the blades of our Nontron Pocket knives are forged in Forge de Laguiole workshop.

The steel comes from the Acieries de Bonpertuis (Isère - France). We mainly use 3 steels for our blades.

The carbon steel XC75 that can be find in antique knives. This steel is very easy to sharpen, wears away more quickly and rusts if it is not cared for.

The French resistent steel T12® is richer in chrome. It is harder than carbon steel but less sensitive to oxidation.

These two steels are forged at 1080°C and subjected to successive tempering, and particularly a hard quench oil. These tempers can guarantee exceptional quality of blade.

Then, we use stainless steel for our steak knives.

The carbon damascus steel (140 layers) is made from a forging technique that involves stacking alternating hard steel and a softer steel. These blades are made by the best French blacksmiths.

Sawing

The COUTELLERIE NONTRONNAISE selects the best pieces of wood and contemporary materials (Corian®…).

After at least 4 years spent in the on site drying room , the boxwood branches are cut with a ribbon saw. These squared drafts are then shaped using a special tool. Then, they are adjusted by hand.

We work as much as we can with species of tree from the French countryside (juniper, boxwood and olivewood). The exotic woods used are sourced in respect of guidelines for the protection of endangered species.

Assembly

5 main steps are necessary to assemble a pocket knife (with a total of around 40 steps) with turning ferrule:

- assembling of the blade

- riveting of the nail

- assembling of the turning ferrule

- fixing of the top disc

Finishing

Two irons are used to wood burn the handles: one for the small stipplings and the other one for the inverted V symbol also called a “fly”. These last ones, the recognisable signs of Nontron knives, are only wood burned on boxwood handles (except on some models such as the n°30 with ball shape and some designed models).

A traditional Nontron pocket knife has 4 lines of stippling and 5 flies.

Once the knife is assembled and woodburned, the knife maker proceeds to the sandpapering, the polishing of the handle, the adjusting of the blade (polishing, centring and tightening) and sharpening.

Quality control

After being thoroughly cleaned each knife is inspected one by one.

If a defect is found the knife is systematically sent back to the knife-maker for reconditioning.

Each knife shipped by COUTELLERIE NONTRONNAISE has to meet its quality assurance commitment.

Produits associés à "La Coutellerie Nontronnaise"

-

Nontron Knife Ball Shape Handle Model Nontron Knife Ball Shape Handle Model

Brass turning ferrule, ball shape handle made from woodburned boxwood), shiny finish. Brass turning ferrule, ball shape handle made from woodburned boxwood), shiny finish.

-

Nontron Pocket Knife Turning Ferrule Model Nontron Pocket Knife Turning Ferrule Model

This model is characterized by its brass turning ferrule, a clog handle made from woodburned boxwood and a shiny finish. This model is characterized by its brass turning ferrule, a clog handle made from woodburned boxwood and a shiny finish.

-

Nontron Knife Violin Model Nontron Knife Violin Model

The Violin knife is a beautiful collector piece! This model has a stainless steel bolster, a woodburned boxwood handle and a matt finish. The Violin knife is a beautiful collector piece! This model has a stainless steel bolster, a woodburned boxwood...

-

Nontron Knife 1914-1918 model Nontron Knife 1914-1918 model

Lock pocket knife manufactured by COUTELLERIE NONTRONNAISE, 1914-1918 model, spring made from Z20C13 stainless steel, woodburned boxwood handle, matt finish. Lock pocket knife manufactured by COUTELLERIE NONTRONNAISE, 1914-1918 model, spring made from Z20C13 stainless steel,...